Abstract

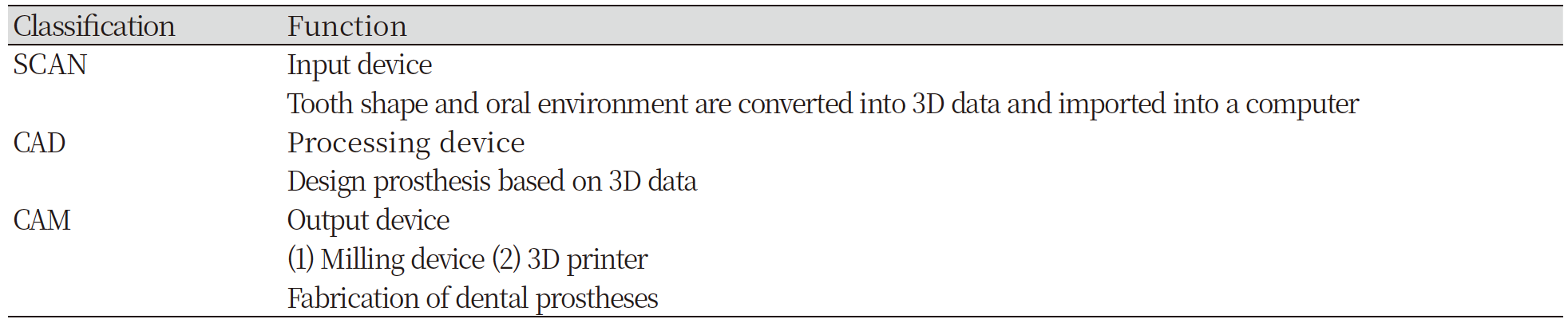

This study aimed to understand the definitions, types, and principles of computer-aided design/computer-aided manufacturing (CAD/CAM) and scanners due to the introduction of digital workflows. This study was based on information from the government’s law and articles published in academic journals. Results: CAD/CAM is a technology that measures the shape three-dimensionally, saves it as data, designs it into the desired shape, and processes the product. Scanners, which are classified as intraoral and extraoral scanners, measure teeth and the intraoral environment three-dimensionally and convert them into three-dimensional (3D). A 3D printer is a machine that creates a 3D object by layering materials based on a 3D drawing. It can be classified into four types according to the extrusion, powder bonding, lamination, and photopolymerization methods. The most used 3D printer methods in dentistry are stereolithograhpy and digital light processing, and they are widely used in prosthetic, surgical, and orthodontic fields. As the dental system is digitized, it is expected that the government will classify the dental hygienist scope of work and the universities will reflect the curriculum; it is necessary to develop excellent dental hygienists, diversify the educational pathways, and establish policies to meet the needs of the increasing number of patients.

Figures & Tables

Table 1. The function of CAD/CAM